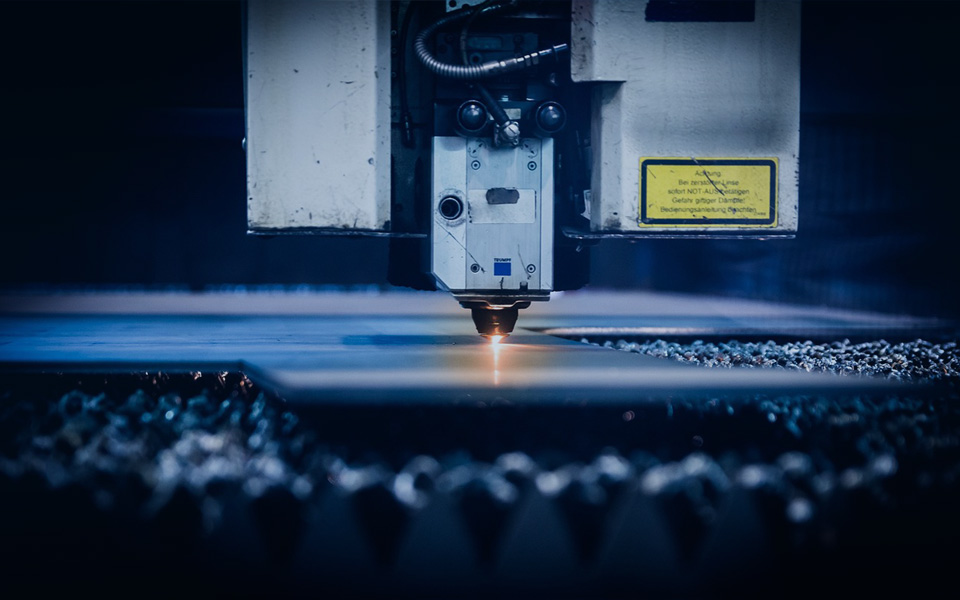

Equipment characteristics

The welding current of transistor power supply rises very fast and can complete the welding process in a short time. The welding heat affected zone is small and there is no spatter in the welding process. It is most suitable for ultra precision welding, such as thin wire, button battery connector, small contact of relay and metal foil.

Product features:

◎ three control modes: constant current, constant voltage, constant current and constant voltage combination mode.

◎ transistor power supply welding large LCD screen, which can display welding current, power and voltage between electrodes.

◎ built in detection function: before formal power on, there can be detection current to confirm the presence or absence of workpieces and the status of workpieces.

◎ energy output polarity switching can be realized.

◎ the actual welding parameters can be output through RS-485 serial port.

◎ 32 groups of energy can be switched arbitrarily through the external port.

◎ input and output signals are complete and can be used with high automation.

| Model | IPR450 |

| Electrical parameters | Maximum current: 5000A |

| No load voltage: 10.2v | |

| Loading power supply: 3-phase 340 ~ 420vac 50 / 60Hz | |

| Rated capacity of transformer: 15KVA | |

| control mode | Primary constant current control |

| control accuracy | Rise 1, rise 2:00 ~ 49ms |

| Time of welding 1: 00 ~ 99ms, time of welding 2: 000 ~ 299ms | |

| Heat 1, heat 2: 800 ~ 5000A | |

| Upper and lower limit setting of current monitoring (peak value) from 0% to 49% | |

| Time setting | Preloading time setting: 000 ~ 999x10ms |

| Cooling time setting of welding head: 00 ~ 99ms | |

| Setting of holding time after welding: 000 ~ 999ms | |

| Cooling mode | Air cooling |

| Peripheral dimensions | 215 (W) X431 (d) x274 (H) mm |

| Package size | 280 (W) x530 (d) X340 (H) mm |

| Total weight | 23 kg |

Dongguan Chuangde Laser Intelligent Technology Co., Ltd

One stop laser welding solution service provider