Precision resistance welding This is a kind of welding method with resistance heat as energy, including electroslag welding with slag resistance heat as energy and resistance welding with solid resistance heat as energy. This paper mainly introduces several resistance welding with solid resistance heat as energy, mainly including spot welding, seam welding, projection welding and butt welding.

When this kind of resistance welding is carried out, the surface of the workpiece to be welded is of primary importance to obtain stable welding quality. Therefore, the contact surface between electrode and workpiece and between workpiece and workpiece must be cleaned before welding.

Precision resistance welding Generally, it is a welding method to make the workpiece under a certain electrode pressure and use the resistance heat generated when the current passes through the workpiece to melt the contact surface between the two workpieces to realize the connection. Larger currents are usually used. In order to prevent arcing on the contact surface and to forge the weld metal, pressure must always be applied during welding.

The contradiction between spot welding, seam welding and projection welding is that the welding current (single phase) is large (thousands to tens of thousands of AMPS), the power on time is short (several cycles to several seconds), the equipment is expensive and complex, and the productivity is high, so it is suitable for mass production. It is mainly used for welding thin plate components with thickness less than 3mm. All kinds of steel, aluminum, magnesium and other non-ferrous metals and their alloys, stainless steel, etc Precision resistance welding。

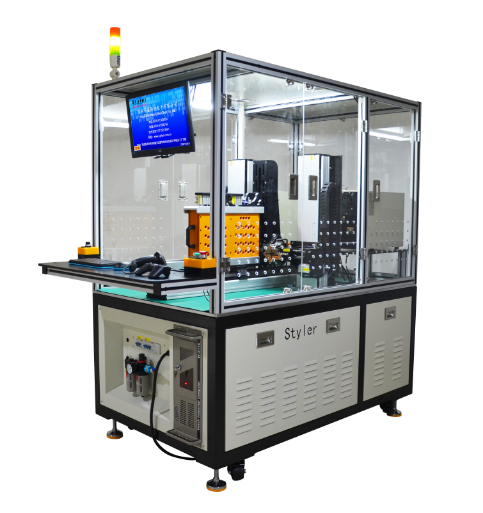

Dongguan Chuangde Laser Intelligent Technology Co., Ltd

One stop laser welding solution service provider